2025.12.26

2025.12.26

Industry News

Industry News

The packaging demands of the chemical sector are uniquely rigorous, requiring solutions that ensure safety, integrity, and logistical efficiency. Within this specialized field, a particular hybrid material is gaining attention: the paper plastic composite bag for chemical industry applications. This type of packaging, which combines layers of paper and plastic films, is increasingly viewed as a balanced option that merges the structural benefits of traditional multi-wall paper sacks with the enhanced moisture and barrier protection of polymer-based packaging.

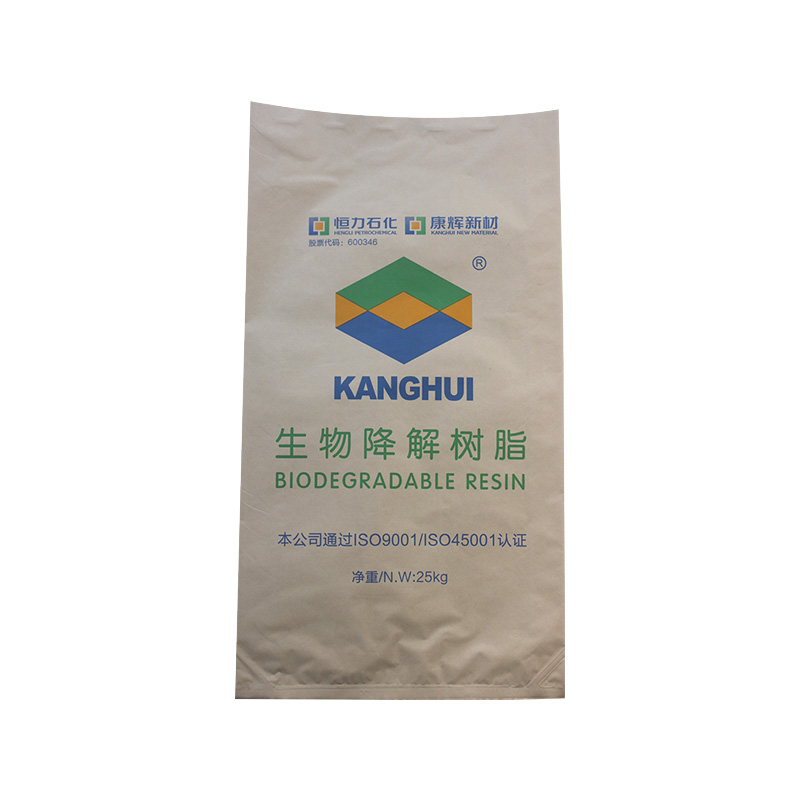

The core construction of a paper plastic composite bag for chemical industry use typically involves kraft paper laminated or co-extruded with one or more layers of polyethylene or polypropylene film. This design capitalizes on the complementary strengths of each material. The paper component provides essential tensile strength, puncture resistance, and a stable, printable surface for branding and handling instructions. It also contributes to the bag's breathability and rigidity, which is advantageous for certain products and stacking. The integrated plastic layer, often on the interior, creates a critical barrier. This barrier protects hygroscopic or sensitive chemical products—such as certain salts, mineral powders, or compounds—from moisture ingress, which can cause clumping, degradation, or loss of efficacy. This makes the paper plastic composite bag for chemical industry shipments a reliable choice for products that require a degree of protection beyond what standard paper bags can offer.

The operational advantages of this bag are notable in the chemical industry supply chain. The composite structure often allows for a reduction in overall material thickness compared to some all-plastic alternatives while maintaining required performance, contributing to lighter weight and potential cost efficiencies in raw materials and shipping. The exterior paper surface offers predominant grip and stackability on pallets, enhancing warehouse safety and space utilization. Furthermore, the paper plastic composite bag can be engineered with specific features such as heat-sealed seams for a secure closure and easy-tear openings for controlled dispensing at the point of use.

A significant factor driving interest in the paper plastic composite bag for chemical industry is its environmental profile, which is subject to ongoing evaluation and innovation. Compared to bags made solely from virgin plastic films, the inclusion of paper—a renewable and widely recycled material—is often perceived favorably. The industry is actively exploring ways to improve the end-of-life scenario for these composite structures. Initiatives include developing mono-material polyolefin layers that are compatible with plastic recycling streams, increasing the use of recycled paper content, and designing for easier separation of material layers where facilities exist. While the recyclability of traditional multi-material composite bags remains a challenge in standard municipal systems, their role in preventing product loss and contamination represents a form of resource efficiency.

The paper plastic composite bag for chemical industry use represents a pragmatic evolution in chemical packaging. It addresses the dual need for robust product protection and a move toward more sustainable material choices. By effectively balancing the structural integrity of paper with the protective barriers of plastic, this type of bag offers a functional and increasingly optimized solution for the safe and efficient handling of a wide range of dry chemical products. As material science advances, the development of next-generation paper plastic composite bag options will likely focus on enhancing circularity while maintaining the critical performance standards demanded by the global chemical industry.