2025.12.12

2025.12.12

Industry News

Industry News

The global chemical sector, a cornerstone of modern manufacturing, relies on a seemingly simple yet critically important component for logistics and handling: specialized bags for chemical industry applications. These are not ordinary sacks; they are engineered packaging solutions designed to ensure the safe, secure, and efficient transport and storage of a vast array of chemical products, from industrial powders and granules to certain types of liquids and resins. The development and manufacturing of these bags for chemical industry use is a field marked by continuous innovation, responding to stringent safety regulations, supply chain demands, and a growing emphasis on environmental responsibility.

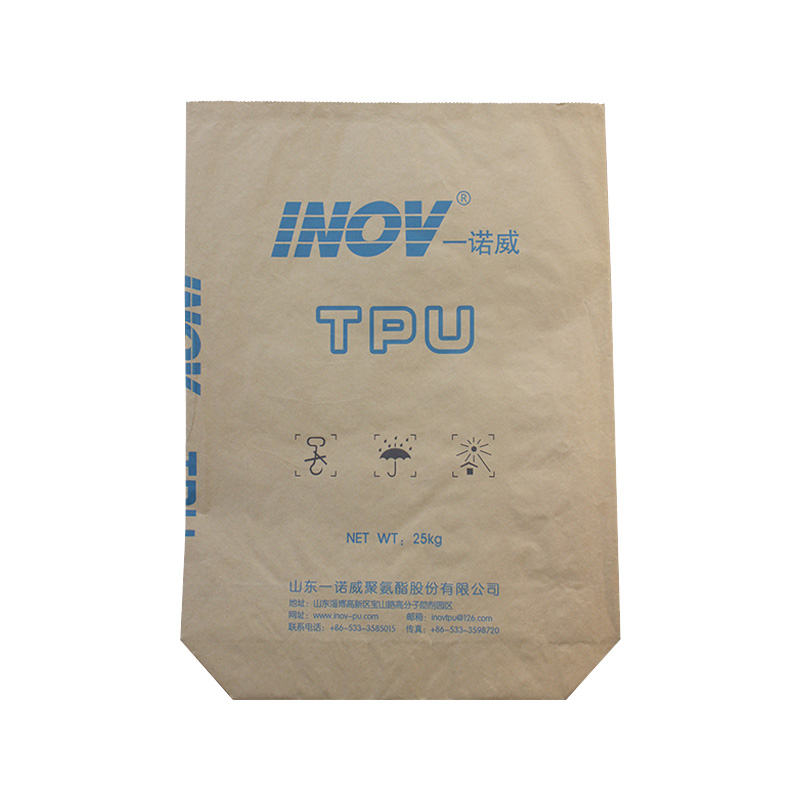

The primary function of any bag for chemical industry applications is containment and protection. This necessitates a multi-faceted design approach. The materials used must form a robust barrier, preventing leakage or contamination that could pose safety hazards, cause product loss, or lead to environmental incidents. Consequently, the construction of these bags for chemical industry shipments often involves multiple layers. A typical structure might include an inner liner of polyethylene or other polymer film for product compatibility and sealing, laminated to woven polypropylene or heavyweight paper for tensile strength and durability. This composite design ensures the bag can withstand the rigors of stacking, palletization, and long-distance transportation common in chemical industry logistics.

Safety remains the paramount concern driving innovation. Modern bags for chemical industry products are subject to rigorous international standards for performance. Features such as heat-sealed seams, sift-proof closures, and moisture-resistant barriers are standard for many products. For hazardous materials, the design of the bag becomes even more critical, often incorporating specific color codes, hazard symbols, and UN certification markings as part of their construction to ensure proper handling throughout the supply chain. The integrity of these bags for chemical industry use is a non-negotiable aspect of operational risk management.

Sustainability is becoming an increasingly powerful driver of change. The traditional linear model of "use and dispose" for packaging is being scrutinized. In response, manufacturers are developing new generations of bags for chemical industry that incorporate recycled materials where performance and safety allow. More significantly, there is a push toward designing bags that are reusable or easier to recycle at their end-of-life. This includes developing mono-material structures that simplify the recycling process and creating take-back programs. The development of more sustainable bags for chemical industry applications aligns with broader corporate environmental goals and meets the expectations of downstream customers.

Functionality and user convenience are also key development areas. Innovations include the integration of easy-pour spouts, tamper-evident features, and ergonomic lifting designs. For bulk handling, Flexible Intermediate Bulk Containers, a specialized form of industrial bag, have revolutionized the movement of large volumes of dry flowable chemicals.

The humble bag for chemical industry use is a sophisticated product at the intersection of materials science, safety engineering, and logistics. Its evolution reflects the broader priorities of the sector it serves: unwavering safety, operational efficiency, and a responsible approach to environmental impact. As regulations tighten and sustainability becomes a core operational pillar, the ongoing innovation in the design and composition of bags for chemical industry applications will remain a vital support to the safe and efficient global movement of chemical products.