2026.01.30

2026.01.30

Industry News

Industry News

Across the agricultural, chemical, construction, and food sectors, the need to efficiently package, store, and transport granular and powdered materials is constant. This demand is met by a broad category of packaging known as bags for granules. This term encompasses a wide variety of sack designs, from small retail packets to large industrial sacks, all engineered to securely contain dry, flowable solids. The selection of appropriate bags for granules is crucial, as the packaging must protect the product from moisture, contamination, and handling damage while facilitating efficient logistics and end-use.

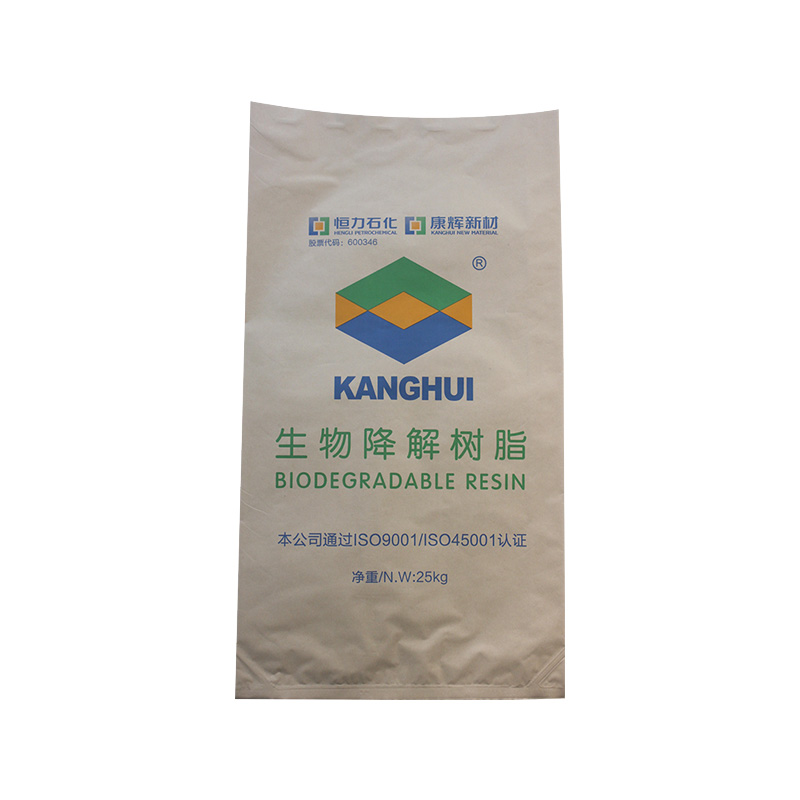

The primary function of bags for granules is reliable containment. Granular materials, such as fertilizer, animal feed, plastic resin, cement, salt, or grain, have specific characteristics like particle size, density, and sometimes abrasiveness. Bags for granules are therefore constructed from materials with suitable strength and barrier properties. Common materials include woven polypropylene for heavy-duty industrial use, multi-wall paper sacks with plastic liners for products requiring moisture protection, and various plastic films for consumer-sized retail packages. The bag's design must consider filling weight, stacking strength for palletization, and the method of closure—whether sewn, heat-sealed, or with a adhesive tape.

A key consideration for bags for granules is product preservation and safety. For hygroscopic materials like certain fertilizers or chemicals, bags for granules often incorporate a polyethylene liner as a moisture barrier. For food-grade products like sugar, flour, or rice, the inner layer must meet relevant safety standards. UV inhibitors may be added to the material for bags for granules intended for outdoor storage. Furthermore, the bag's construction must prevent sifting—the leakage of fine particles through seams or the fabric weave—which can lead to product loss, contamination, and dust hazards.

The application spectrum for bags for granules is vast and defines their specifications. In agriculture, 25kg or 50kg bags for granules are standard for fertilizers and seeds. The construction industry uses similar heavy-duty bags for granules for sand, mortar mix, and aggregates. For consumers, smaller, often printed bags for granules package pet food, bird seed, potting soil, and charcoal. In manufacturing, bags for granules transport raw materials like plastic pellets to injection molding facilities. Each application dictates the bag's size, material, printing for branding and instructions, and features like carrying handles or easy-pour spouts.

Logistics and handling efficiency are major factors in the design of bags for granules. The bags must be compatible with automated filling lines, palletizing robots, and manual handling. Features like sewn-in loops (for FIBCs), gusseted sides for stable stacking, and anti-slip surfaces are important. The shift towards more sustainable practices is also influencing the market for bags for granules, driving demand for options made from recycled materials, with higher recyclability, or designed for reuse in a circular system.

Innovation in bags for granules focuses on enhancing sustainability, smart packaging, and performance. Trends include the development of lighter-weight yet stronger materials to reduce plastic usage, the integration of compostable or bio-based films for certain applications, and the use of water-based inks for reduced environmental impact. Smart packaging features, such as QR codes for traceability or integrated sensors to monitor bag integrity during shipping, are emerging. As global supply chains seek greater efficiency and reduced environmental footprint, the humble bag for granules will continue to evolve, remaining an indispensable, if often overlooked, link in the journey of countless essential materials from producer to end-user.